Jacksonville Duval County 904-346-1266

St Augustine St Johns County 904-824-7144

Orange Park Clay County 904-264-6444

Jacksonville Beaches Duval County 904-246-3969

Fernandina Nassau County 904-277-3040

Macclenny Baker County 904-259-5091

Palm Coast Flagler County 386-439-5290

Daytona Volusia County 386-253-4911

Serving all of Florida and Georgia at 904-346-1266

EMAIL LARRY@1STPROP.COM (feel free to email your bidding packages here)

- 24 hour emergency service

- Commercial repipes

- High-pressure water jet drain cleaning – large and small diameter

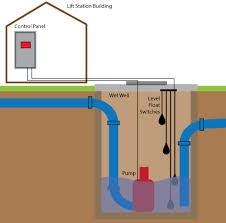

- Lift station installation, repair and maintenance

- Permit-required confined-space entry

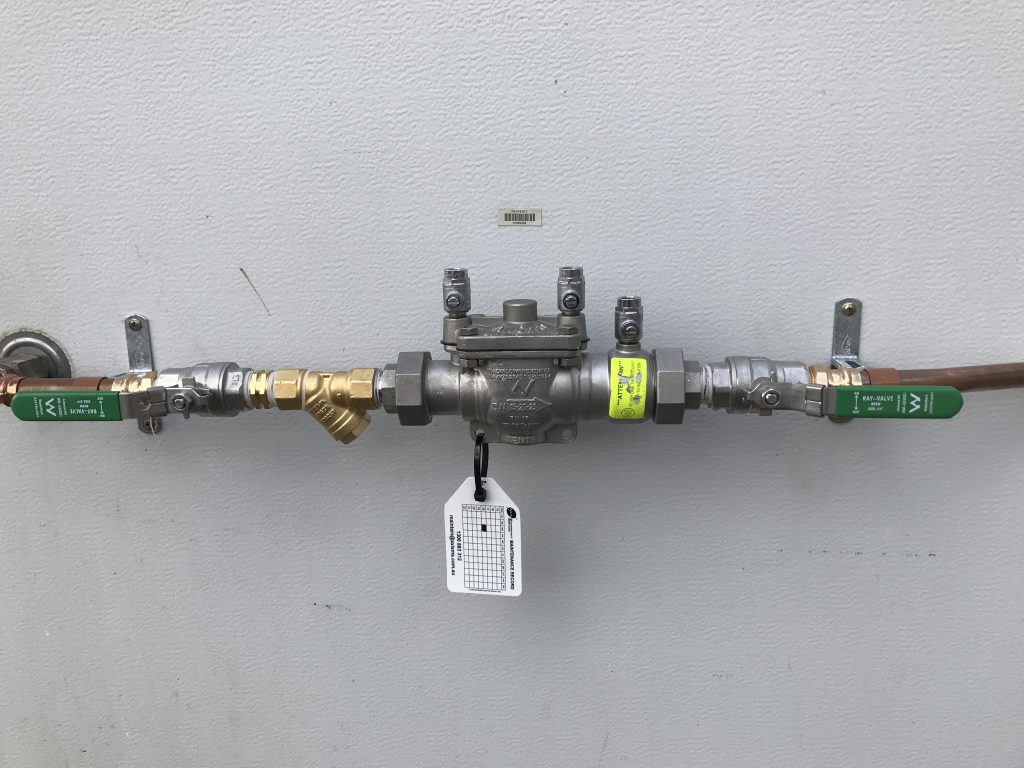

- Backflow installation, testing and repair

- Electronic line location

- Large or small water heater repair

- Fiber-optic pipeline video inspection

- Grease trap and septic tank pumping

- Grease trap and septic tank installation

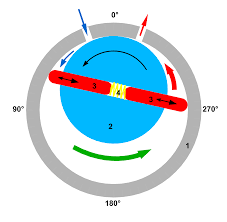

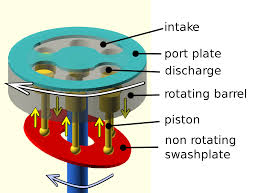

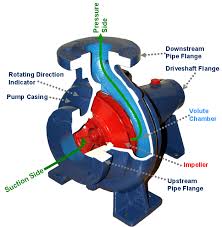

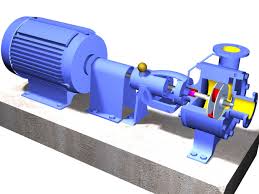

- Industrial pump repair & installation

- Emergency spills

- All types of commercial plumbing repair

- Track work and tank cleaning

- Scheduled service programs for your grease traps designed to meet your specific situation

- Industrial tank pumping and cleaning

- Lift station pump installation, cleaning and repair

- Sludge removal

- Sediment removal

- Vac-Com work

- Large and small diameter high-pressure pipe jetting

- Wet and dry solids removal

- Storm drain system cleaning and repair

- Backflow installation testing and repair

- Permit-required confined-space entry

- All types of industrial plumbing repair

- Oil-Water Separation

- Truck wash holding tank pump out

- Emergency spills

- Pipe jetting

- Pipeline video inspection

- Storm drain cleaning/repair

- Confined space

- Tubs, toilets, sinks and facets – repair and replacement

- Remodeling

- Shower Pans

- Slab Leaks

- Water softener, filtration & drinking water systems

- All types of residential plumbing repairs

- 7 day a week service

- Saturday 8am to 4pm same as weekday rates

- Sewer and drain field cleaning

- Sewer repair or sewer line replacement

- Pipeline inspection

- Water heaters

- Septic Tank installation, pumping, problem resolving

- Septic systems cleaning

- Drain field repair and installation

- Back flow installation testing and repair

- Drain field mound removal

- Septic-to-city sewer conversion

- Sewage systems, sewage pump treatment

- Septic tank lid replacement

- sludge waste removal

- Tank abandonment

Residual fats, oils and grease (FOG) is a by-product from food service establishments. Typically, FOG enters a facility’s plumbing system from ware washing, floor cleaning, and equipment sanitation. Sanitary sewer systems are neither designed nor equipped to handle the FOG that can accumulate on the interior of the sewer collection system pipes from improperly maintained discharges. These accumulations may cause a sanitary sewer overflow (SSO). A SSO is the unintentional flow of untreated sewage onto the ground or into a facility, home, or waterway. SSOs create a health risk to the public, damage property, and pollute our environment.Frequently Asked Questions

How to Properly Clean your Small Grease Trap (units under 50 gallons) Tool & Materials 1. A large trash can 2. 2 or 3 trash can liners/bags (thick or heavy duty) 3. Absorbent material (Floor dry available at auto parts store or clay kitty litter) 4. Proper hand tools and safety equipment to open trap a. hex head wrench (allen wrench), screw driver/small pry bar, scraper, rubber gloves and safety glasses 5. Tools for removing contents a. scoop of some type b. scraper (for cleaning the internal parts) c. wet/dry vacuum (optional) 6. Towels/rags Let’s begin: 1. Prepare your work area (clear area of debris, bleach bottles, and other cleaners). 2. Line the trash can with the garbage bags. 3. Add absorbent material (floor dry or kitty litter) into the lined trash can. This will soak up the water and liquid waste making transport of waste to the dumpster cleaner and safer. Dig in: 1. Remove the lid of the grease trap. 2. Observe the manner in which the internal parts are installed because you’ll have to re-install them properly when you finish cleaning the trap. 3. Begin removing contents of the grease trap by dipping or vacuuming the waste products from the inside of the grease trap 4. Remove all contents until grease trap is empty 5. Do NOT use hot water, degreasers, or soaps to clean the interior of the trap. 6. Scrape all the inside walls, baffles, and screens to insure movement of water through unit. 7. Inspect and note condition of tank, baffle and all removable parts. Schedule repairs or replacement as needed. 8. Make sure the grease trap has been properly reassembled (all internal parts are in their proper place). 9. Examine the gasket for damage. Replace if necessary – never use tube silicone as a gasket . 10. Clean and re-install rubber gasket and reposition lid on tank. Ensure all screws and holddowns are in place and properly tightened. 11. Ensure enough absorbent material has been placed in bag to soak up all excess liquids. Add more if needed. Securely tie the bag of waste closed so that it does not leak. 12. Place bag in the garbage (solid waste) dumpster or designated receptacle. It is illegal to dump grease trap or kitchen waste into storm drains, ponds or outdoor areas. Document and report your maintenance as required by Industrial Pretreatment Regulation: 1. Complete an entry on the small trap maintenance log to be kept onsite. 2. Complete an entry on the small trap pump-out report which should be mailed in monthly. Cleaning your Grease Trap frequently is “a good thing” for the following reasons: 1. Fewer smells and odors – The longer waste is trapped the stronger the odors it generates. Longer trap life- Rotting foods create acids which eat away at the internal components and tank. Address: Callahan Pumps 5508 Wilmin Way Suite # 4 Zip Code: 32207 |