On-demand water heaters

Tankless Water Heaters

Stand-alone appliances for quickly heating water for DHW (Domestic Hot Water) are known in North America as tankless heaters, elsewhere as multipoint heaters, geysers or Ascots. In Australia and New Zealand there was a similar wood fired appliance known as the chip heater.

A common arrangement where hot-water space heating is employed is for the boiler to also heat potable water giving a continuous supply of DHW without any extra equipment required. Appliances capable of supplying both space-heating and DHW are known as combination (or “combi“) boilers.

Although on-demand heaters can give a continuous supply of DHW, the rate at which they can produce it is limited by the thermodynamics of heating water from the available fuel supplies.

Plumbing repairs and new construction

Plumbing Repairs and New Construction

FREE ESTIMATES

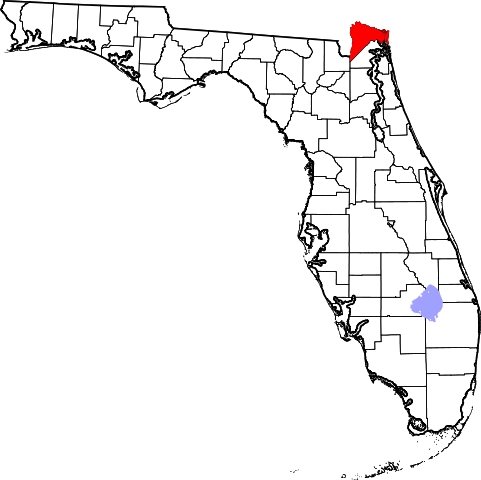

Jacksonville Duval County 904-346-1266

St Augustine St Johns County 904-824-7144

Orange Park Clay County 904-264-6444

Jacksonville Beaches Duval County 904-246-3969

Fernandina Nassau County 904-277-3040

Macclenny Baker County 904-259-5091

Palm Coast Flagler County 386-439-5290

Daytona Volusia County 386-253-4911

GAINESVILLE ALACHUA COUNTY 352-335-8555

Serving all of Florida and Georgia at 904-346-1266

EMAIL LARRY@1STPROP.COM (feel free to email your bidding packages here)

Plumbing (from the Latinplumbum for lead as pipes were once made from lead) is the skilled trade of working with pipes, tubing and plumbing fixtures for drinking water systems and the drainage of waste. A plumber is someone who installs or repairs piping systems, plumbing fixtures and equipment such as water heaters. The plumbing industry is a basic and substantial part of every developed economy due to the need for clean water, and proper collection and transport of wastes.

Plumbing also refers to a system of pipes and fixtures installed in a building for the distribution of potable water and the removal of waterborne wastes. Plumbing is usually distinguished from water and sewage systems, in that a plumbing system serves one building, while water and sewage systems serve a group of buildings or a city.

Plumbing was extremely rare until the growth of modern cities in the 19th century. At about the same time public health authorities began pressing for better waste disposal systems to be installed. Earlier, the waste disposal system merely consisted of collecting waste and dumping it on ground or into a river. Standardized earthen plumbing pipes with broad flanges making use of asphalt for preventing leakages appeared in the urban settlements of the Indus Valley Civilization by 2700 B.C. Plumbing originated during the ancient civilizations such as the Greek, Roman, Persian, Indian, and Chinese civilizations as they developed public baths and needed to provide potable water, and drainage of wastes. The Romans used lead pipe inscriptions to prevent water theft. Improvement in plumbing systems was very slow, with virtually no progress made from the time of the Roman system of aqueducts and lead pipes until the 19th century. Eventually the development of separate, underground water and sewage systems eliminated open sewage ditches and cesspools. Most large cities today pipe solid wastes to treatment plants in order to separate and partly purify the water before emptying into streams or other bodies of water.

Water systems of ancient times relied on gravity for the supply of water, using pipes or channels usually made of clay, lead, bamboo or stone. Present-day water-supply systems use a network of high-pressure pumps, and pipes are now made of copper, brass, plastic, or other nontoxic material. Present-day drain and vent lines are made of plastic, steel, cast-iron, and lead. Lead is not used in modern water-supply piping due to its toxicity.

The ’straight’ sections of plumbing systems are of pipe or tube. A pipe is typically formed via casting or welding, where a tube is made through extrusion. Pipe normally has thicker walls and may be threaded or welded, where tubing is thinner-walled and requires special joining techniques such as ‘brazing’, ‘compression fitting’, ‘crimping’, or for plastics, ’solvent welding’.

In addition to the straight pipe or tubing, many fittings are required in plumbing systems, such as valves, elbows, tees, and unions. The piping and plumbing fittings and valves articles discuss these features further.

Plumbing fixtures are designed for the end-users. Some examples of fixtures include water closets (also known as toilets), urinals, bidets, showers, bathtubs, utility and kitchen sinks, drinking fountains, ice makers, humidifiers, air washers, fountains, and eye wash stations.

Plumbing equipment, not present in all systems, include, for example, water meters, pumps, expansion tanks, backflow preventers, filters, water softeners, water heaters, wrenches, heat exchangers, gauges, and control systems.

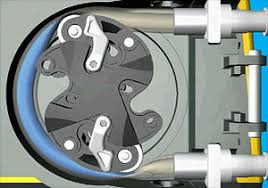

Now there is equipment that is technologically advanced and helps plumbers fix problems without the usual hassles. For example, plumbers use video cameras for inspections of hidden leaks or problems, they use hydro jets, and high pressure hydraulic pumps connected to steel cables for trench-less sewer line replacement.

The major categories of plumbing systems or subsystems are:

- Potable cold and hot water supply

- Traps, drains, and vents

- Septic systems

- Rainwater, surface, and subsurface water drainage

- Fuel gas piping

For their environmental benefit and sizable energy savings hot water heat recycling units are growing in use throughout the residential building sectors. Further ecological concern has seen increasing interest in grey-water recovery and treatment systems.

Firestopping is required where mechanical penetrants traverse fire-resistance rated wall and floor assemblies, or membranes thereof. This work is usually done worldwide by the insulation trade and/or specialty firestop sub-contractors.

Much of the plumbing work in populated areas is regulated by government or quasi-government agencies due to the direct impact on the public’s health, safety, and welfare. Plumbing installation and repair work on residences and other buildings generally must be done according to plumbing and building codes to protect the inhabitants of the buildings and to ensure safe, quality construction to future buyers. If permits are required for work, plumbing contractors typically secure them from the authorities on behalf of home or building owners. In the United Kingdom the professional body is the newly Chartered Institute of Plumbing and Heating Engineering (educational charity status)and it is true that the trade still remains virtually ungoverned; there are no systems in place to monitor or control the activities of unqualified plumbers or those home owners who choose to undertake installation and maintenance works themselves, despite the health and safety issues which arise from such works when they are undertaken incorrectly – see Health Aspects of Plumbing (HAP) published jointly by the World Health Organization(WHO) and the World Plumbing Council (WPC) WPC has subsequently appointed a representative to the World Health Organization to take forward various projects related to Health Aspects of Plumbing.

A trap primer (or trap seal primer) is a plumbing device or valve that adds water to traps. The water seals in traps are needed to prevent sewer gases from entering buildings, but because this water is exposed to the air, it is subject to evaporation over time in infrequently used floor drains, leading to the release of sewer gas into the environment. The trap primer mitigates this problem by injecting water, either directly or indirectly, into the trap to maintain the water seal indefinitely.

Building codes may require trap primers for some traps, especially for where experience has shown that there are isolated and/or infrequently used drains such as basement floor drains (which hopefully are only used when the basement is flooded). Where explosion hazards are high, specifying trap primers, whether required or not by code, is wise. Trap primers do require maintenance and replacement, so they should be installed in accessible locations.

There are many types of trap primers. The simplest, typically for a floor drain’s trap, is simply a connection from a nearby sink’s drain so that when the sink is used, some of the water flow is diverted into one or more traps. More common is a primer that is connected to the potable water supply and activates when pressure fluctuations are sensed, such as the flushing of a nearby water closet. Others depend on occupancy sensors or timers. Several manufacturers produce laundry faucets with a built-in trap seal primer outlet.

In infrequently used floor drains where such a primer does not exist, evaporation can be mitigated a few different ways:

- Routinely adding water to the floor drain

- Pouring a small amount of vegetable or mineral oil into the drain to just cover the trap’s water surface. The oil floats on the surface of the water and creates a liquid seal preventing further evaporation. Mineral oil tends to be a better option, as it does not go rancid, where vegetable oil does. Any environmental impact from its discharge is negligible compared to the contents that can be flushed out of a flooded basement.

Poor venting or windy conditions can cause water seals to be siphoned or blown out; for these cases, the drain must be refilled.

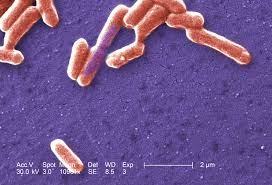

In modern plumbing, a drain-waste-vent (or DWV) is a system that removes sewage and greywater from a building and vents the gases produced by said waste. Waste is produced at fixtures such as toilets, sinks and showers, and exits the fixtures through a trap, a dipped section of pipe that always contains water. All fixtures must contain traps to prevent gases from backing up into the house. Through traps, all fixtures are connected to waste lines, which in turn take the waste to a soil stack, which extends from the building drain at its lowest point to above and out of the roof. Through the building drain, the waste is removed from the building and taken to a sewage line, which leads to a septic system or a public sewer. Cesspits are generally prohibited in developed areas.

The venting system, or plumbing vents, consists of pipes leading from fixtures to the outdoors, usually via the roof. Vents provide for relief of sewer gases, admission of oxygen for aerobic sewage digestion, and maintenance of the trap water seals which prevent sewer gases from entering the building. Every fixture is required to have an internal or external trap; double trapping is prohibited by plumbing codes. With exceptions, every plumbing fixture must have an attached vent. The top of stacks must be vented too, via a stack vent, which is sometimes called a stink pipe.

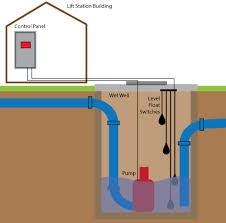

DWV systems maintain neutral air pressure in the drains, allowing flow of water and sewage down drains and through waste pipes by gravity. As such, it is critical that a downward slope be maintained throughout. In relatively rare situations, a downward slope out of a building to the sewer cannot be created, and a special collection pit and grinding lift ’sewage ejector’ pump are needed. By comparison, potable water supply systems operate under pressure to distribute water up through buildings.

A sewer pipe is normally at neutral air pressure compared to the surrounding atmosphere. When a column of waste water flows through a pipe, it compresses air in the pipe, creating a positive pressure that must be released or it will push back on the waste stream and downstream traps’ water seals. As the column of water passes, air must flow in behind the waste stream or negative pressure (suction) results. The extent of these pressure fluctuations is determined by the fluid volume of the waste discharge.

Excessive negative air pressure, behind a ’slug’ of water that is draining, can siphon water from trap seals at plumbing fixtures. Generally, a toilet outlet has the shortest trap seal, making it most vulnerable to being emptied by induced siphonage. An empty trap can allow noxious sewer gasses to enter a building.

On the other hand, if the air pressure within the drain becomes suddenly higher than ambient, this positive transient could cause waste water to be pushed into the fixture, breaking the trap seal, with dire hygiene and health consequences if too forceful. Tall buildings of three or more stories are particularly susceptible to this problem. Vent stacks are put in parallel to waste stacks to allow proper venting in tall buildings.

To prevent the problems of high pressure in a drain system, sewer pipes will usually vent via one of two mechanisms.

Most residential buildings’ drainage systems in North America are vented directly through the buildings’ roofs. The DWV pipe is typically ABS or PVC DWV-rated plastic pipe equipped with a flashing to prevent water entering the buildings. Older homes may use copper, iron, lead or clay pipes, in rough order of increasing antiquity.

Under many older building codes, a vent stack, a pipe leading to the main roof vent, is required to be within a five foot radius of the draining fixture (sink, toilet, shower stall, etc.). To allow only one vent stack, and thus one roof protrusion as permitted by local building code, sub-vents may be tied together and exit a common vent stack.

A blocked vent is a relatively common problem caused by anything from leaves, to dead squirrels, to ice dams in very cold weather. Symptoms range from bubbles in the toilet bowl when it is flushed, to slow drainage, and all the way to siphoned (empty) traps and sewer gases entering the building. When a fixture trap is venting properly, a “sucking” sound can often be heard as the fixture empties out.

Air admittance valves (AAVs) are pressure-activated, one-way mechanical vents, used in a plumbing system to eliminate the need for conventional pipe venting and roof penetrations. A discharge of wastewater causes the AAV to open, releasing the vacuum and allowing air to enter plumbing vent pipe for proper drainage. Otherwise, the valve remains closed, preventing the escape of sewer gas and maintaining the trap seal. Using AAVs can significantly reduce the amount of venting materials needed in a plumbing system, increase plumbing labor efficiency, allow greater flexibility in the layout of plumbing fixtures, and reduce long-term roof maintenance problems associated with conventional vent stack roofing penetrations.

While some state and local building departments prohibit AAVs, the International Residential and International Plumbing Codes allow it to be used in place of a vent-through-the-roof. AAV’s are certified to reliably open and close a minimum of 500,000 times, (approximately 30 years of use) with no emanation of sewer gas; and some manufacturers claim their units are tested for up to 1.5 million cycles, or at least 80 years of use. Air Admittance Valves have been effectively used in Europe for more than two decades. U.S. manufacturers offer warranties that range from 20 years to lifetime.

Drainage and venting systems require not only pipe, but also many fittings which add considerably to their cost of construction. But fittings such as “clean-outs” enhance the maintainability of the systems.

One of the primary responsibilities of local governments is to provide potable water and treatment of sewage. The potable water side is called the WTP or Water Treatment Plant; and the waste/sewage removal system is called the WWTP Waste Water Treatment Plant; A municipal system’s WTP treats water and brings it to home in compliance with federal, state, and local regulations governing water quality. The WWTP provides for the removal and treatment of waste water; the Waste water treatment facility or natural waste site (Usually a body of water or river) is typically as far away from inhabited areas as practical. Where a building is unable to connect to a municipal sewage system, the Waste/Sewage treatment is accomplished by means of a septic system and periodic hauling-off of the solids produced.

FREE ESTIMATES- (904) 346-1266

Address:

Callahan Pumps

5508 Wilmin Way

Suite # 4

Zip Code: 32207